|

Patented Gas Anchor

This patented gas anchor

also can solve the sand problem.

Installation: You need

connect two or more used tubing with a plug (for storage the sand) to the

bottom of the gas anchor. Then connect the top coupling to the bottom of

the tubing of the build-in rod pump

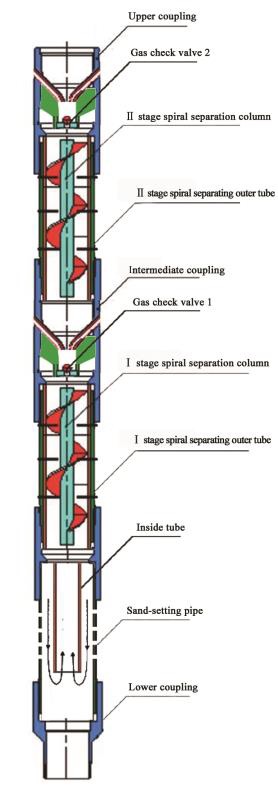

Principle:

1) First separation: up stroke brings both liquid and

gas into sand setting pipe, gas floats to the top. Down stroke makes gas

escape fro the upper part of the sand-setting pipe;

2) 2nd separation: the remaining gas enter

into Stage I spiral separation unit. Centrifugal effect makes liquid move

to the tubing wall and push to the Stage II spiral separation unit. The gas

escaped through center check valve I

3) 3rd separation: same principle as the 2nd

separation

4) First separation: up stroke brings both liquid and

gas into sand setting pipe, gas floats to the top. Down stroke makes gas

escape for the upper part of the sand-setting pipe;

5) 2nd separation: the remaining gas enter

into Stage I spiral separation unit. Centrifugal effect makes liquid move

to the tubing wall and push to the Stage II spiral separation unit. The gas

escaped through center check valve I

6) 3rd separation: same principle as the 2nd

separation

7) First separation: up stroke brings both liquid and

gas into sand setting pipe, gas floats to the top. Down stroke makes gas

escape for the upper part of the sand-setting pipe;

8) 2nd separation: the remaining gas enter

into Stage I spiral separation unit. Centrifugal effect makes liquid move

to the tubing wall and push to the Stage II spiral separation unit. The gas

escaped through center check valve I

9) 3rd separation: same principle as the 2nd

separation

|

![]()