![]()

Anti-corrosive Sucker Rod

HDPE Lined Rods

![]()

Go www.RodsDepot.com for details

or Call 281-683-2797 or Quote@ibyOUTLET.com

This international patented

product applied in severe corrosion and slant wells with

five times longer cycle life and two times longer extended tubing life

comparing to the conventional sucker rod.

Features

and Advantage

If you

have serious sour problems, this product will save you a lot of money.

(1)

Spray welding corrosion resistant alloy on both ends of

the sucker rod, high bonding strength, the tools will not damage the corrosion

protection layer;

(2)

Polymer anticorrosive materials are coated on the middle of sucker rod

body, coating materials help reducing anticorrosion sucker rod

production cost;

(3)

Casting a hoop on the spray welding layer

and coating joint to prevent corrosion medium permeate into

the coating;

(4) Smooth surface, no scaling,

no wax;

(5) Resistance

to various acids, bases, salts and corrosive gases.

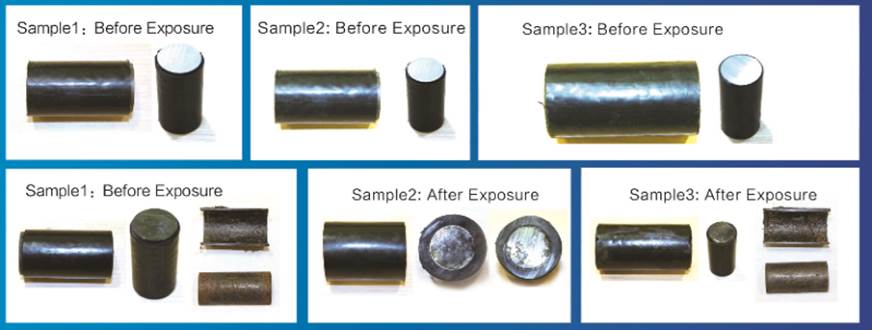

Our

products passed the 3rd party lab full test in Canada. (see

following sample test)

Technical

Parameters

(1) Coating thickness: 2 mm (0.079 inch)

(2) Spray welding thickness: 0.1-0.15 mm (0.0039-0.0059

inch)

(3) Heat resistance: -20¡æ to 80¡æ (-4¨H to 176¨H)

Precautions£º

(1) When

hot wash wells, the water temperature should not exceed the specified

temperature 80 ¡æ (176 ¨H).

(2) Avoid collisions with hard

objects and sharp objects during the operation.

(3) Hard

and sharp objects percussion is strictly prohibited.